Introduction

Truck mounted cranes are essential equipment used in various industries such as construction, transportation, and logistics. These powerful machines are designed to lift heavy loads and provide flexibility and efficiency in handling materials. However, like any other equipment, truck mounted cranes require regular maintenance to ensure their longevity, reliability, and most importantly, safety. In this comprehensive guide, we will delve into the importance of truck mounted crane maintenance, the key components that require attention, maintenance best practices, and tips to prevent breakdowns and accidents.

Importance of Truck Mounted Crane Maintenance

Proper maintenance of truck mounted cranes is crucial for several reasons. First and foremost, regular maintenance helps ensure the safety of operators, workers, and bystanders. A well-maintained crane is less likely to experience mechanical failures or malfunctions, reducing the risk of accidents and injuries on the job site.

Secondly, maintenance plays a significant role in extending the lifespan of the crane. By addressing minor issues promptly and conducting routine inspections and servicing, operators can prevent major breakdowns and costly repairs that could otherwise shorten the crane's operational life.

Furthermore, regular maintenance can improve the crane's performance and efficiency. A properly maintained crane operates more smoothly, consumes less fuel, and delivers optimal lifting capacity, contributing to overall productivity and profitability for businesses.

Key Components of Truck Mounted Crane Maintenance

To ensure the proper functioning of a truck mounted crane, operators must pay close attention to key components that require regular maintenance. These components include:

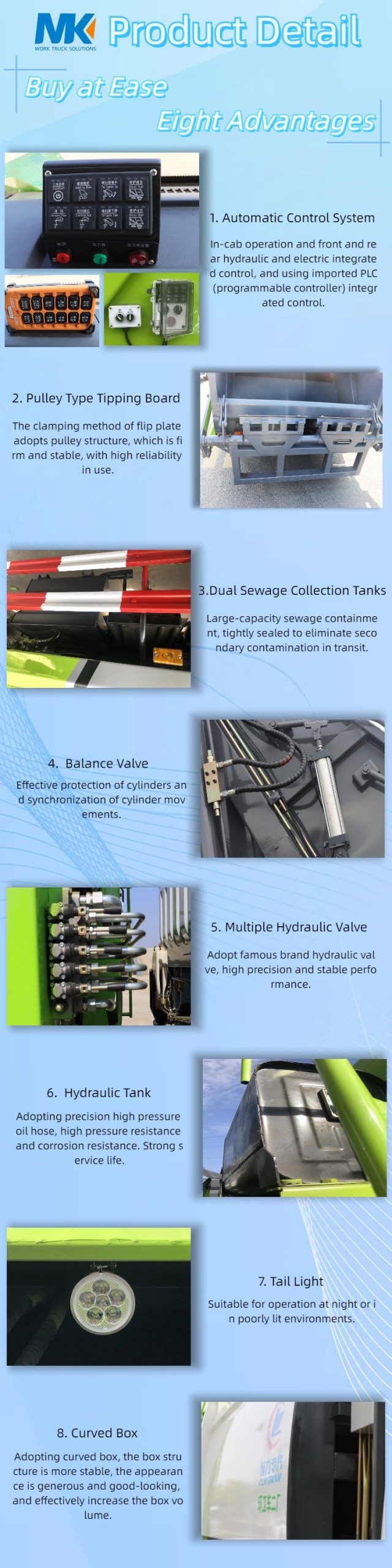

1. Hydraulic System: The hydraulic system is a critical part of a truck mounted crane as it powers the lifting mechanism. Regular inspection of hydraulic hoses, fittings, seals, and fluid levels is essential to prevent leaks, overheating, and system failures.

2. Boom and Jib: The boom and jib are responsible for extending the reach of the crane. Inspecting these components for signs of wear, cracks, or misalignment is crucial to prevent structural failures during lifting operations.

3. Wire Ropes and Cables: Wire ropes and cables are used to lift and lower loads. Checking for signs of fraying, kinks, or corrosion is vital to ensure the integrity and strength of these components.

4. Controls and Safety Devices: The control system and safety devices, such as limit switches and overload protection systems, must be inspected regularly to ensure proper functioning and compliance with safety standards.

5. Structural Components: Inspecting the chassis, outriggers, and stabilizers for signs of damage, rust, or misalignment is essential to maintain the stability and structural integrity of the crane.

Maintenance Best Practices

To maintain a truck mounted crane in optimal condition, operators should follow these best practices:

1. Create a Maintenance Schedule: Develop a regular maintenance schedule based on the manufacturer's recommendations and operational usage. Schedule routine inspections, servicing, and preventive maintenance tasks to keep the crane in top condition.

2. Train Operators: Ensure that operators are properly trained in crane operation and maintenance procedures. Provide training on how to conduct pre-operational checks, recognize warning signs, and report any issues promptly.

3. Keep Records: Maintain detailed maintenance records, including inspection reports, service logs, and repair records. This information can help track the crane's maintenance history, identify recurring issues, and plan future maintenance tasks.

4. Clean and Lubricate: Keep the crane clean and free from dirt, debris, and contaminants that can cause premature wear and corrosion. Regularly lubricate moving parts to reduce friction and extend component life.

5. Conduct Load Tests: Periodically conduct load tests to verify the crane's lifting capacity and performance. Ensure that the crane can safely lift the maximum rated load without exceeding its limits.

6. Monitor Fluid Levels: Check hydraulic fluid, engine oil, coolant, and other fluid levels regularly and top up as needed. Contaminated or low fluid levels can cause system failures and damage components.

7. Address Issues Promptly: If any issues or abnormalities are detected during inspections or operations, address them promptly. Delaying repairs can lead to more significant problems and downtime.

Preventing Breakdowns and Accidents

To prevent breakdowns and accidents involving truck mounted cranes, operators should adhere to the following safety tips:

1. Conduct Pre-Operational Checks: Before each use, conduct thorough pre-operational checks to ensure that the crane is in good working condition. Inspect all components, controls, and safety devices for proper function.

2. Follow Load Limits: Never exceed the crane's rated load capacity or reach. Overloading the crane can cause structural failures, tip-overs, and accidents.

3. Use Outriggers and Stabilizers: Deploy outriggers and stabilizers as recommended by the manufacturer to stabilize the crane during lifting operations. Ensure that the crane is on level ground and properly supported.

4. Maintain Safe Distances: Keep bystanders, workers, and other equipment at a safe distance from the crane during operation. Use barricades or warning signs to prevent unauthorized access to the work area.

5. https://www.worktruckmaker.com : Avoid operating the crane in high winds, heavy rain, or other adverse weather conditions that could compromise safety. Follow manufacturer guidelines for safe operating conditions.

6. Communicate Effectively: Maintain clear communication between the crane operator, signal person, and other workers involved in lifting operations. Use hand signals, radios, or other communication devices to coordinate movements.

Conclusion

Proper maintenance of truck mounted cranes is essential to ensure their longevity, reliability, and safety. By following maintenance best practices, conducting regular inspections, and addressing issues promptly, operators can maximize the performance and lifespan of their cranes while minimizing the risk of accidents and breakdowns. Remember, safety should always be the top priority when operating a truck mounted crane. By investing time and effort in maintenance, operators can enjoy efficient and safe crane operations for years to come.